Shared from www.theguardian.com.

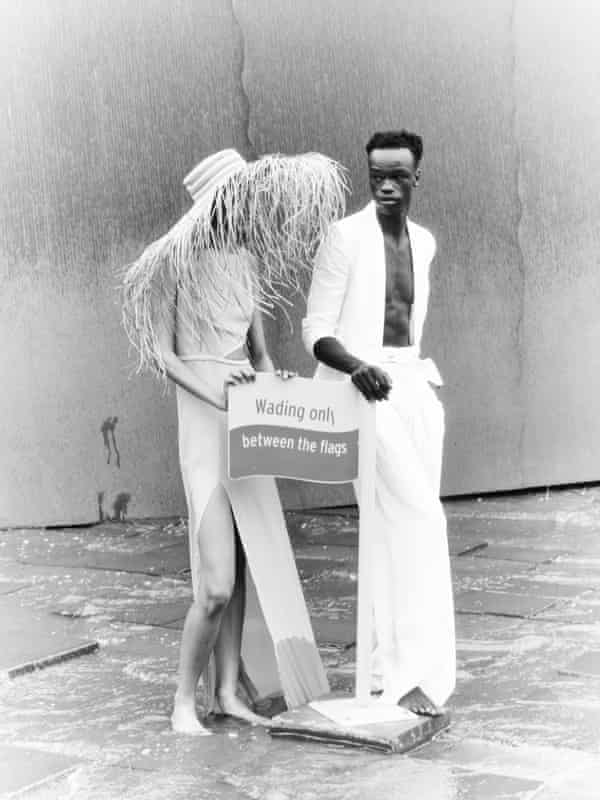

It’s unlikely the Cranbourne Royal Botanical Gardens will ever see anything like it again: a group of models, wearing designer clothes, wander its beautifully crafted Australian Garden. Clad in suits and gowns, many walk barefoot through water features and across grey concrete.

The models are here to shoot a digital runway, a partnership between Australian Made and the Melbourne fashion festival. Every garment featured in the film is made in Australia and licensed to carry the Australian Made logo: the familiar green triangle with its yellow kangaroo.

The runway is pitched to elevate Australian designers in the global market and, when it launches on 9 March, consumers in the United Kingdom and America will be able to shop from it. But sourcing product for the film revealed limitations in Australia’s manufacturing capacity. For instance, the footwear – or lack thereof.

The film’s stylist, Emily Ward, describes finding shoes that met the Australian Made requirements as challenging. “I sort of went down the line exploring some brands … and then we realised they weren’t actually made here, so we had to move on.”

She settled on two brands who make their products locally, Nelson Made and Alias Mae. But even then, certain styles did not meet Australian Made requirements.

To use the Australian Made logo, an item has to meet the test of “substantial transformation”. According to Ben Lazzarro, the company’s chief executive, this means “you’ve got to cut and sew here”.

If you take the example of a shirt, he says, “as long as you cut that material here, sew and form it into a shirt here, you can legally make a ‘made in Australia’ claim,” even if the fabric has been imported.

The reason it was harder for Ward to find shoes is because often the leather for footwear is imported pre-cut. The shoes she did source for the runway were from designers, “handcrafting shoes on a smaller scale, who aren’t in the mass market”.

“R.M. Williams used to be made locally in Australia,” she says, as did other more established brands. But “they’re not 100% Australian Made any more”, though last year the owners of R.M. Williams suggested they may return to 100% local manufacturing.

The runway featured nine Australian labels, including Bianca Spender and Viktoria and Woods, two brands that have manufactured locally since their inception. Margie Woods, the creative director of Viktoria and Woods, described the campaign as “a really important, positive step” for brands that do make the effort to manufacture here. “It is a lot easier to go offshore.”

Woods describes the challenges of making in Australia as multifaceted. She says the most common is the cost of labor; another is “quite a big skills shortage here”. Finally, the lack of machinery and advanced technology means certain categories like outerwear, denim, leather and complicated knitwear are particularly difficult to make locally.

Woods recently invested $130,000 in a knitting machine to support one of her makers. She says the purchase, which is sizeable for an independent designer, “will allow us to produce 4,000 more garments in Australia per year”.

Mary Lou Ryan, the co-founder of Bassike – another brand committed to local manufacturing – says Australia has fallen behind. “There hasn’t really been a) the infrastructure and government support and b) … the support from Australian brands to get behind the industry either.”

Ryan suggests government funding for technology and automated machinery, bringing back skills through tertiary education and trade programs and more support for immigration could help Australia catch up.

Subsidies, skilled migration visas and technological investment are suggestions echoed by Woods, who says “from a government level something can be done … to keep local manufacturing alive”.

Australian brands, meanwhile, need to deliver commitment and continuity, Ryan says. If brands come in and try it for six months, “then find it’s too hard and go back offshore … things won’t move ahead”.

Sign up to receive Guardian Australia’s weekend culture and lifestyle email.

Bianca Spender says designers need to be conscious of the fragility of manufacturing businesses. “Designers can devastate manufacturers,” she says. Things like delayed payments, asking for lots of work on season then nothing the next and a lack of commitment “can leave them out of pocket very quickly”.

Lazzarro is aware of the manufacturing issues the fashion industry faces, but he explains it is not the role of Australian Made to get involved. “We’re not a lobby or advocacy group,” he says, “we’re a licensing and a marketing group”.

The Australian Fashion Council (AFC) has taken a different approach. In 2020, they approached the then minister for industry, science and technology, Karen Andrews, and requested support to increase demand for all Australian fashion, regardless of whether or not it was produced here.

Leila Naja Hibri, the chief executive of the AFC, says “if we only look at manufacturing and making, you’re really regressing because we’re not thinking of the soft skills. Australians are amazing at design and product development.

“We absolutely want Australian products to be made here,” she says. But since most of the industry is making offshore, she believes the path to healthy local manufacturing runs through championing all Australian fashion businesses.

The result of this lobbying was a grant of $1m from the Department of Industry Science, Energy and Resources to create an Australian fashion certified trademark that can be licensed by brands. The mark is set to be launched at the end of March, and has different criteria to Australian Made’s “substantial transformation” requirement.

According to Naja Hibri, it will look at things like ownership, whether most of a brand’s workforce is in Australia, and whether the brand pays taxes here.

Naja Hibri says that only increasing demand for Australian fashion more broadly will “give brands the fiscal headspace to be able to expand.” At which point, they can “work on projects to skill workers, hire the right people and manufacture locally”.

Images and Article from www.theguardian.com